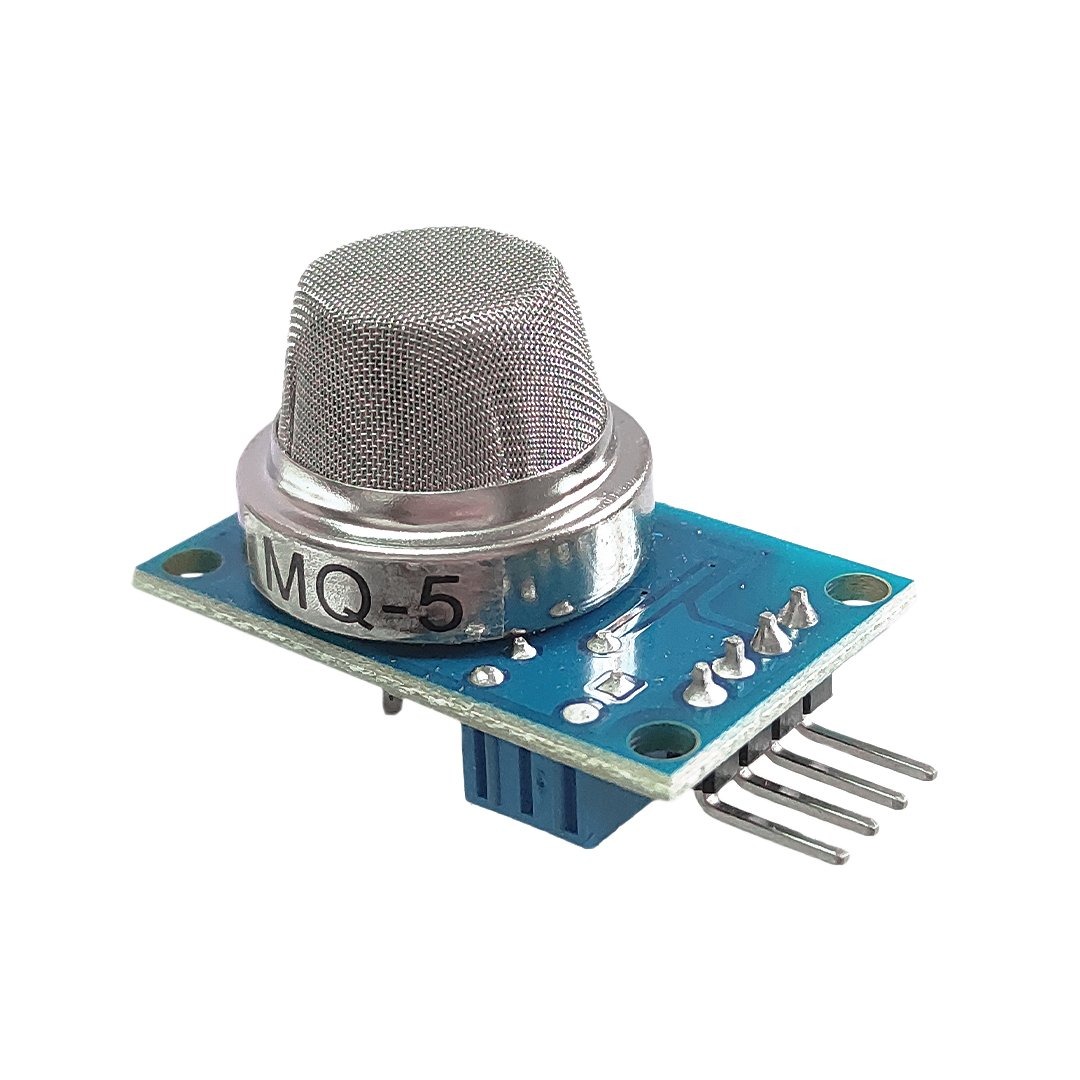

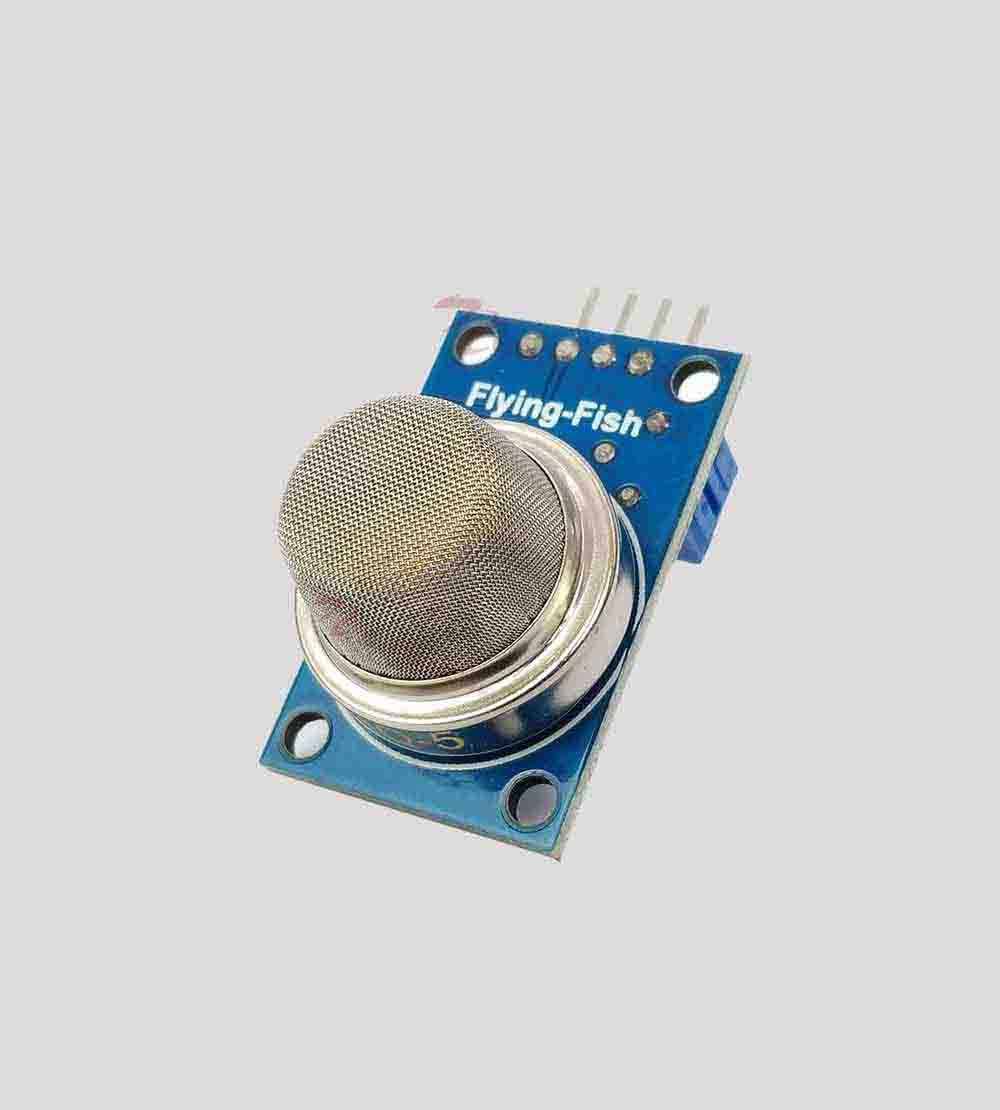

MQ-5 LPG Gas Sensor Module — Overview

The MQ-5 LPG Gas Sensor Module is a reliable sensor designed to detect liquefied petroleum gas (LPG) and other combustible gases such as methane and carbon monoxide. It delivers stable analog output, fast response, and robust operation for home safety, industrial leak detection, environmental monitoring, and maker projects.

Key Features

- High sensitivity to LPG and other combustible gases

- Wide detection range: 300 to 10,000 ppm

- Analog voltage output (0 to 5V) proportional to gas concentration

- Fast response time: ≤ 10 seconds

- Durable design for long-term monitoring and consistent performance

- Simple 4-pin interface for quick hookup to microcontrollers and breakout boards

Specifications

- Gases Detected: LPG (Liquefied Petroleum Gas), methane, carbon monoxide, and other combustible gases

- Detection Range: 300 to 10,000 ppm

- Operating Voltage: 5V DC

- Output Type: Analog (0-5V)

- Response Time: ≤ 10 seconds

- Preheat Time: Minimum 24 hours for optimal stability and accuracy

- Operating Temperature: -20°C to +50°C

- Dimensions: Approx. 32mm x 22mm x 27mm

Applications

- Gas leak detection in homes, kitchens, and industrial facilities

- Safety monitoring systems and automatic shutoff triggers

- Environmental air quality monitoring where combustible gases are a concern

- DIY and maker projects using Arduino, Raspberry Pi and other microcontrollers

Integration and Wiring Tips

The MQ-5 module is designed for easy integration into embedded systems and hobby projects.

- Power: Supply stable 5V DC to the module. Avoid voltage spikes to protect the sensor element.

- Outputs: The module provides an analog voltage (0 to 5V) proportional to gas concentration. Many breakout boards also expose a digital output for threshold alarms.

- Microcontroller Connection: Read analog output directly with Arduino analog inputs. For Raspberry Pi, use an external ADC since Pi has no native analog inputs.

- Pin Layout: Typical 4-pin breakout: VCC, GND, AOUT (analog out), DOUT (digital out on many boards).

- Signal Conditioning: Use smoothing or averaging in software to reduce noise. Calibrate thresholds experimentally for reliable alarms.

Calibration, Preheat and Best Practices

- Preheat: Allow the sensor to preheat for at least 24 hours before first use for stable readings.

- Calibration: Calibrate in fresh air and, if possible, verify readings with a known gas concentration or reference sensor.

- Placement: Install the sensor near potential leak sources but avoid direct drafts and high humidity locations for best accuracy.

- Maintenance: Periodically check baseline readings and replace the module when sensitivity degrades after extended use.

Why Choose the MQ-5 Module

The MQ-5 offers a cost effective, easy-to-use solution for gas leak detection and environmental monitoring. Its wide detection range, analog output, and quick response time make it well suited for both prototype development and deployed safety systems.

Typical Projects

- Kitchen LPG leak alarm with automatic ventilation or shutdown

- Smart home safety system that sends push notifications on detected leaks

- Portable methane detection units for field testing

- Classroom and maker workshops for learning sensor interfacing and IoT

Safety Notice

This module is intended for detection and monitoring purposes. It is not a certified industrial safety device on its own. For life safety or compliance installations, use certified gas detectors and follow local codes and standards.

Note: Images are for illustration purposes only.

Reviews

There are no reviews yet