Overview

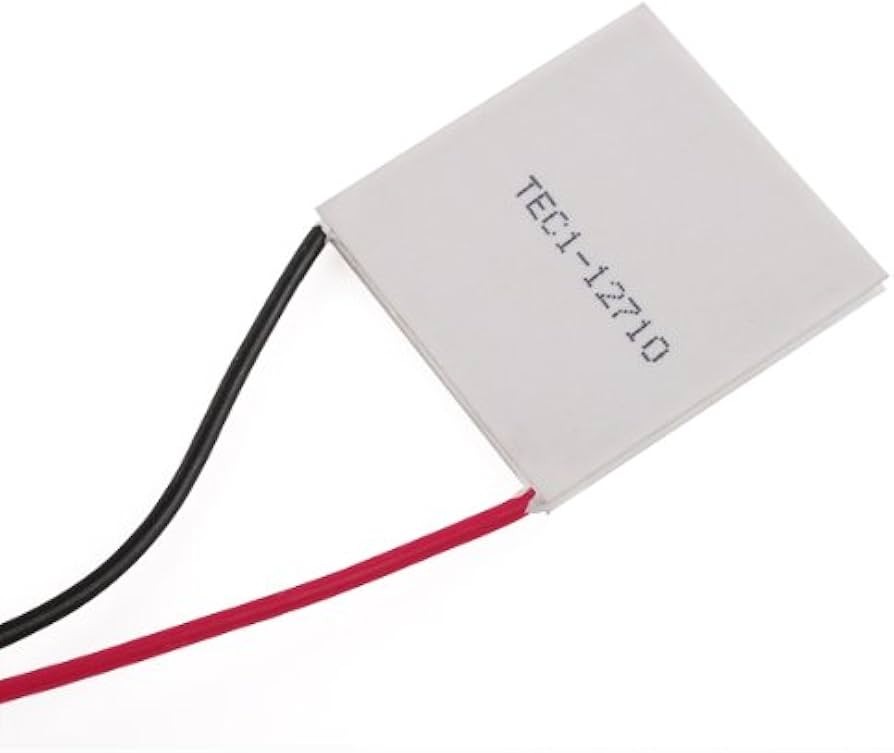

The Thermoelectric Cooler Peltier Module TEC1-12710 is a compact, solid-state thermoelectric cooler that uses the Peltier effect to transfer heat from one side of the module to the other. Designed for reliable temperature control, the TEC1-12710 is perfect where quiet, compact and maintenance-free cooling is required.

Key Features and Benefits

- Peltier effect cooling: Creates a temperature differential to move heat efficiently without refrigerants.

- 12V DC operation: Compatible with common power supplies and battery systems for flexible integration.

- High cooling capacity: Up to 60W heat dissipation with a maximum current of 6A, suitable for small to medium heat loads.

- Silent and compact: Solid-state design with no moving parts makes it ideal for noise-sensitive environments.

- Durable construction: Built from quality materials to ensure long service life under repeated use.

- Environmentally friendly: No refrigerants used; reduced environmental impact compared to compressor-based systems.

Technical Specifications

- Model: TEC1-12710

- Operating voltage: 12V DC

- Maximum current: 6A

- Maximum cooling power (heat dissipation): 60W

- Form factor: Compact Peltier module for easy mounting

Why Choose the TEC1-12710 Peltier Module?

The TEC1-12710 delivers focused, reliable cooling where traditional fan-and-heat-sink or compressor solutions are impractical. Its compact size, low noise and solid-state reliability make it an excellent choice for hobbyists and professionals who need precise thermal control in tight spaces.

Real-World Applications

- Electronics cooling: Cooling CPUs, GPUs, power regulators and other high-performance components.

- Portable coolers and mini-refrigeration: Integration into portable food/drink coolers, medical sample boxes and tiny refrigerators.

- Robotics: Temperature regulation for motors, sensors and battery packs to maintain optimal performance.

- Automotive: Localized cooling for temperature-sensitive components or small cabin cooling applications.

- Lab and medical equipment: Precise thermal control for instruments and samples without vibration or noise.

Installation and Best Practices

Required components

- 12V DC power supply rated for at least 6A (plus margin).

- Appropriate heat sink and/or fan to dissipate heat from the hot side.

- Thermal interface material (thermal paste or pads) for optimal thermal contact.

- Temperature sensor or controller if active regulation is needed.

Step-by-step setup

- Connect the TEC1-12710 to a stable 12V DC power source capable of delivering up to 6A.

- Apply thermal paste or a thermal pad to the cold side and mount it to the device or surface you need to cool, ensuring firm and even contact.

- Mount the hot side to an appropriately sized heat sink and, if possible, add forced-air cooling (fan) to improve heat dissipation.

- Power up and monitor temperatures. Use a controller or sensors to avoid overcooling and to protect the module from excessive temperature differentials.

Safety Tips and Handling

- Never exceed the specified 12V and 6A ratings to avoid damaging the module.

- Ensure good heat sinking on the hot side; without adequate dissipation the module will heat up and lose effectiveness.

- Prevent condensation by controlling humidity and avoiding rapid temperature swings on the cooled surface.

- Use a current-limited power supply during testing to protect the device and connected electronics.

Maintenance

- Inspect thermal interface materials and heat sink mounting periodically and replace thermal paste or pads as needed.

- Keep the heat sink and surrounding area clean and free of dust for consistent performance.

Note: Images are for Illustration Purposes Only

Reviews

There are no reviews yet