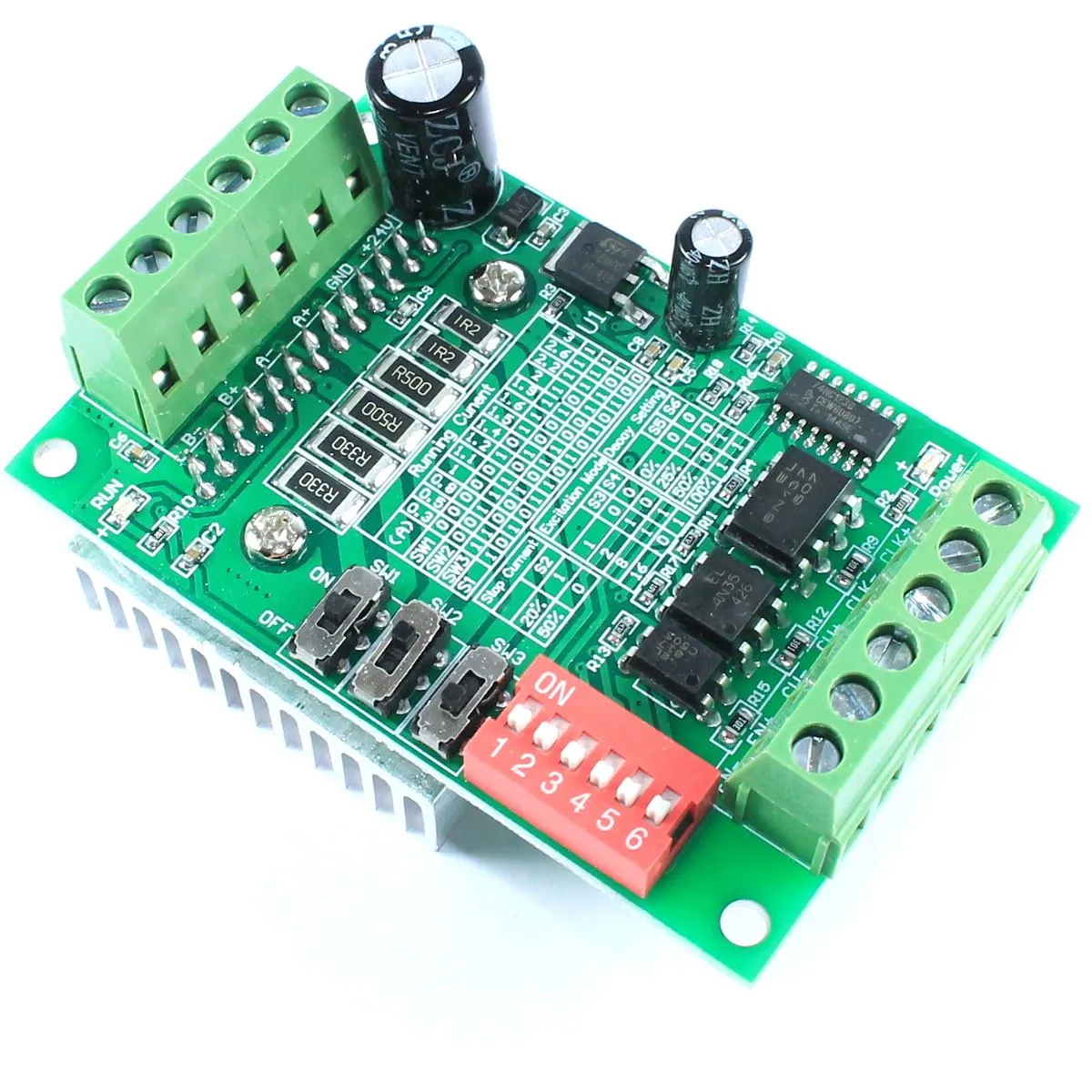

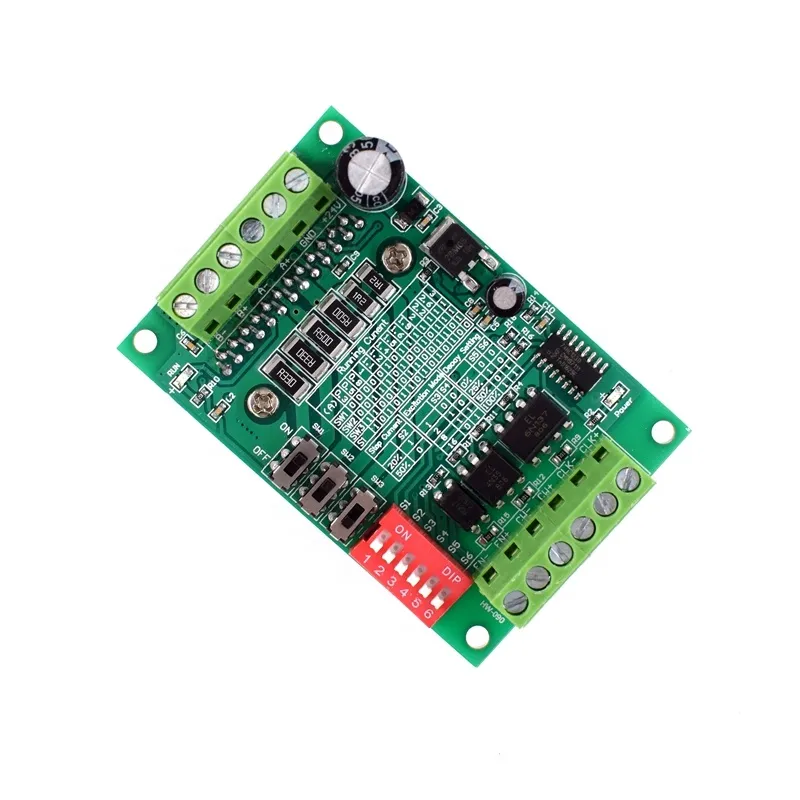

TB6560 Stepper Motor Driver 3A – Overview

The TB6560 Stepper Motor Driver 3A is a reliable, high-performance driver module based on the Toshiba TB6560 IC. Designed for bipolar stepper motors (2-phase, 4-wire or 6-wire), this compact module delivers smooth motion and accurate microstepping control for CNC, robotics, 3D printing, and automation projects.

Key Features

- IC: Toshiba TB6560 for proven stepper control performance

- Output current: Up to 3A per phase (adjustable for motor and heat management)

- Input voltage: 10 to 35V DC to support a wide range of motors and systems

- Microstepping modes: Full, 1/2, 1/8, 1/16 selectable for smoother motion and higher resolution

- Optical isolation on signal inputs to reduce electrical noise and improve reliability

- Protection features: Over-current, under-voltage, and thermal shutdown to protect the driver and motor

- Compact, easy to mount and integrate into CNC and robotics frames

Technical Specifications

- Model: TB6560 Stepper Motor Driver 3A

- Driver IC: Toshiba TB6560

- Motor type: Bipolar stepper motors (2-phase, 4-wire or 6-wire)

- Supply voltage: 10 V to 35 V DC

- Output current: Adjustable up to 3 A per phase

- Microstepping: Full, 1/2, 1/8, 1/16

- Signal interface: Optically isolated inputs (STEP, DIR, ENABLE, etc.)

- Protections: Over-current, under-voltage, thermal shutdown

- Typical applications: CNC, laser engraving, 3D printing, robotics, automation

Applications

- CNC routers, mills, and engravers

- Laser cutters and laser engravers

- 3D printers and pick-and-place machines

- Robotics and automated motion control systems

- DIY CNC and stepper motor control projects

Installation, Wiring, and Setup Tips

- Always disconnect power before wiring. Verify motor coil wiring (A+/A-, B+/B-) to avoid damage.

- Set the microstepping and current limit via the on-board jumpers and potentiometer according to your motor datasheet.

- Use a sufficiently rated power supply in the 10 to 35 V DC range; higher voltages improve high-speed torque but increase heat.

- Ensure adequate cooling and ventilation. Use heatsinks and consider active cooling for sustained high current operation.

- Keep signal wiring short and twisted where possible to reduce noise; use the optical isolation features for improved reliability.

Microstepping and Current Adjustment

Microstepping reduces vibration and improves motion resolution. Choose full step for maximum torque, or 1/8 and 1/16 for smoother, higher-resolution moves. Adjust the driver current to match the motor’s rated current while leaving headroom for safe operation. Lowering current reduces heat but also reduces torque.

Protection and Reliability

The TB6560 driver includes over-current, under-voltage, and thermal shutdown protections to guard against common fault conditions. Optical isolation on the inputs helps prevent ground loops and noise from affecting control electronics. These features make the driver suitable for both hobby and industrial-style projects.

Compatibility and Integration

The TB6560 Stepper Motor Driver 3A works well with common motion controllers, Arduino-based systems, GRBL-based CNC controllers, and other step/dir control boards. Its compact footprint and standard pinout make it simple to mount on machine frames or inside control enclosures.

Note: Images are for Illustration Purposes Only

Reviews

There are no reviews yet