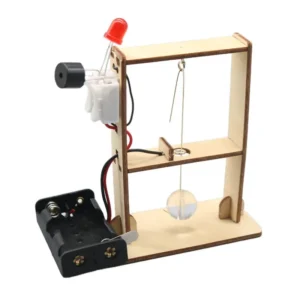

Overview: T-M233 Pumping Unit DIY Learning Kit

The T-M233 Pumping Unit DIY Learning Kit is an educational build-and-learn project that demonstrates how mechanical motion, gears, cranks, and linkages convert rotary energy into repetitive lifting action. Students assemble a functional mini pumping unit that simulates large-scale oil well pumps and water extraction systems using safe, durable materials.

Why this STEM kit matters

- Clear, hands-on demonstration of mechanical engineering principles

- Explains energy conversion from electrical power to mechanical motion

- Builds practical skills: assembly, wiring, troubleshooting, and testing

Key Features

- Functional pumping mechanism: Converts motor rotation into reciprocating motion for realistic demonstration

- STEM learning focus: Covers levers, torque, gears, cranks, linkages, and basic hydraulic concepts

- Hands-on assembly: Encourages observation, testing, and iterative problem solving

- Electric motor driven: Includes a mini DC motor compatible with 3V to 6V DC operation

- Durable, safe materials: Eco-friendly pre-cut wood and high-quality plastic parts

- Customizable: Parts can be painted or decorated after assembly for creative projects

What is included in the package

- Pre-cut wooden pumping unit frame set

- Mini DC motor

- Battery holder (2 × AA)

- Switch module

- Linkage and crank mechanism parts

- Screws, wires, and assembly accessories

- Step-by-step instruction guide

Specifications

- Operating voltage: 3V to 6V DC

- Motor type: Mini DC motor

- Material: High-quality wood and plastic components

- Power source: 2 × AA batteries (not included)

- Assembly time: 30 to 45 minutes

- Skill level: Beginner to intermediate

Educational Value and Classroom Uses

This pumping unit DIY kit is ideal for classroom demonstrations, STEM workshops, maker spaces, and science fairs. It supports lesson plans in mechanical engineering, physics, and industrial automation by providing a visible model of how torque, leverage, and linkages operate in real machines.

- Teaches how mechanical motion is used in pumping systems and industrial machinery

- Demonstrates torque, rotational energy, and mechanical advantage with hands-on experiments

- Encourages problem-solving, logical thinking, and design iteration

- Inspires interest in mechanical engineering, automation, and applied mechanics

Assembly Tips and Best Practices

- Sort and inspect all parts before starting; verify motor orientation and wire connections

- Tighten screws incrementally to avoid warping the wooden frame

- Test the motor and switch with batteries before final assembly to confirm operation

- Use small amounts of wood glue for permanent connections, or leave removable for classroom reuse

Safety and Care

- Recommended for ages 10 and up with adult supervision

- Do not operate the motor without proper battery rating; avoid short circuits

- Keep small parts away from young children to prevent choking hazards

- Wipe components with a dry cloth; avoid prolonged exposure to moisture

Suggested Projects and Experiments

- Measure how changing crank length alters stroke and lifting motion

- Compare motor speeds at 3V, 4.5V, and 6V to demonstrate speed and torque trade-offs

- Modify the linkage geometry to explore mechanical advantage and efficiency

- Create a classroom challenge to improve lift height or reduce power consumption

Ideal For

Teachers, STEM club coordinators, hobbyists, and young engineers looking for a practical, low-cost demonstration of pumping mechanics and energy conversion.

Note: Images are for illustration purposes only.

Reviews

There are no reviews yet