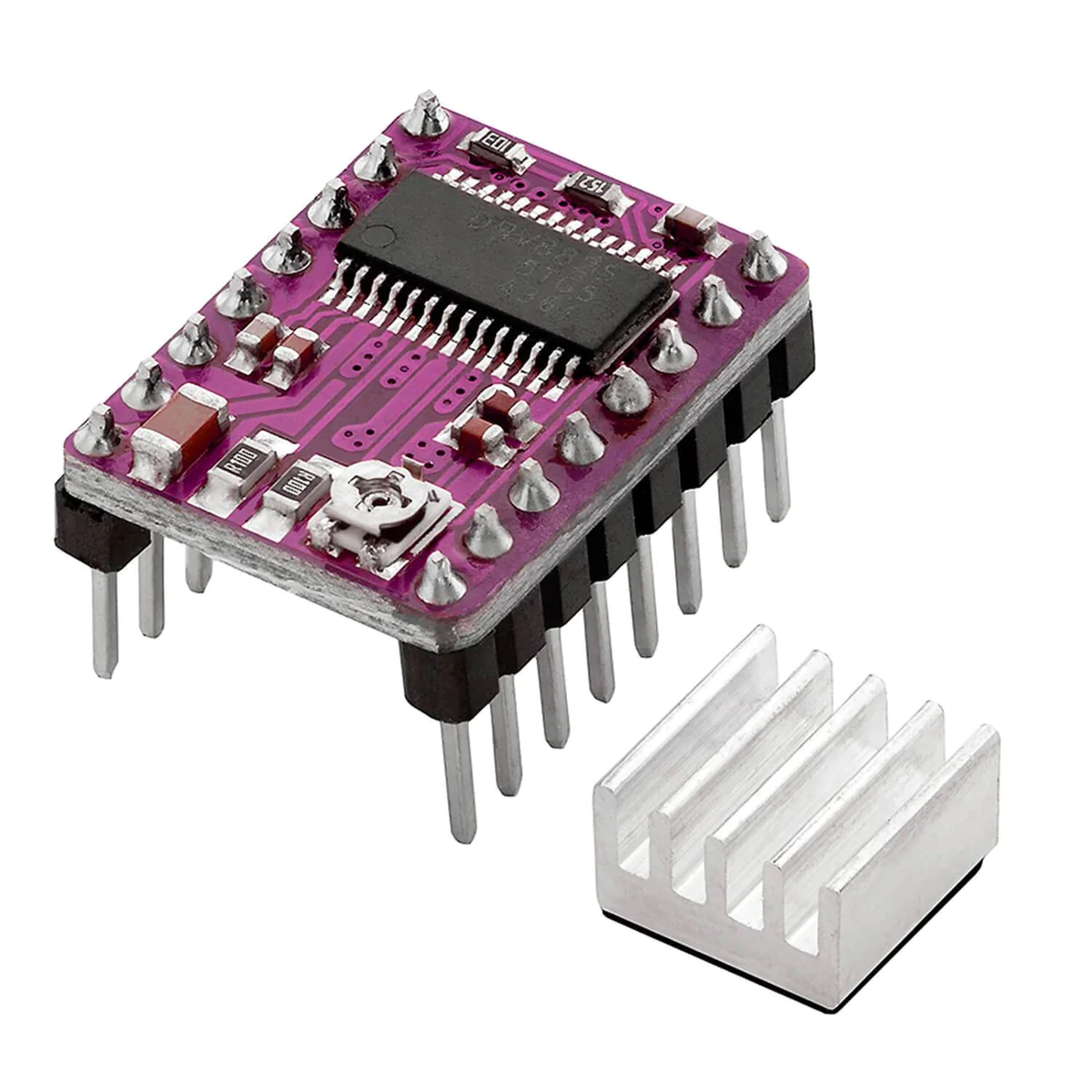

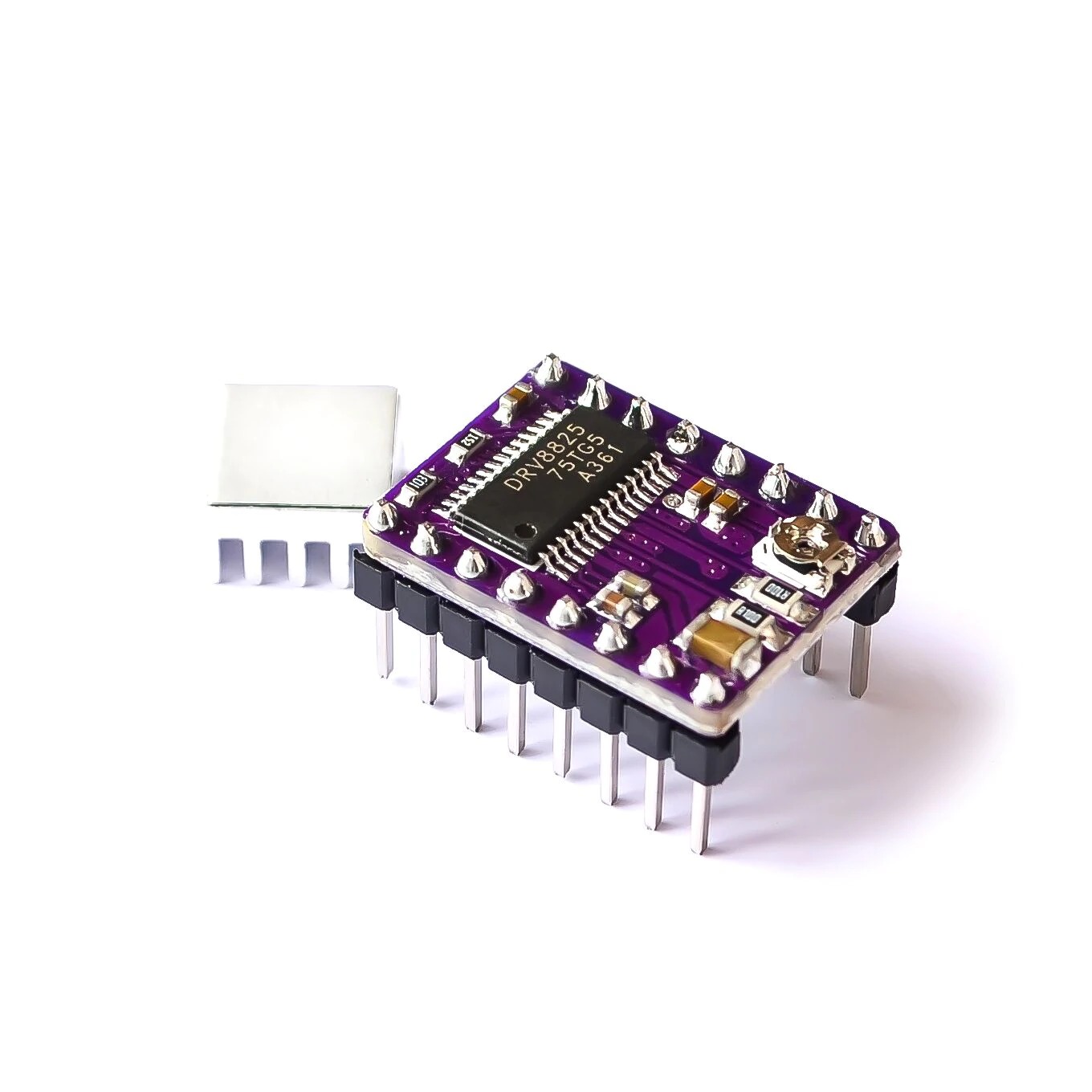

DRV8825 Stepper Motor Driver Module with Aluminum Heat Sink

The DRV8825 Stepper Motor Driver Module with Aluminum Heat Sink is a high-performance driver designed for precise, reliable control of bipolar stepper motors. With integrated thermal management and robust protection features, this module is ideal for 3D printers, CNC machines, robotics, and other precision motion applications.

Key Features

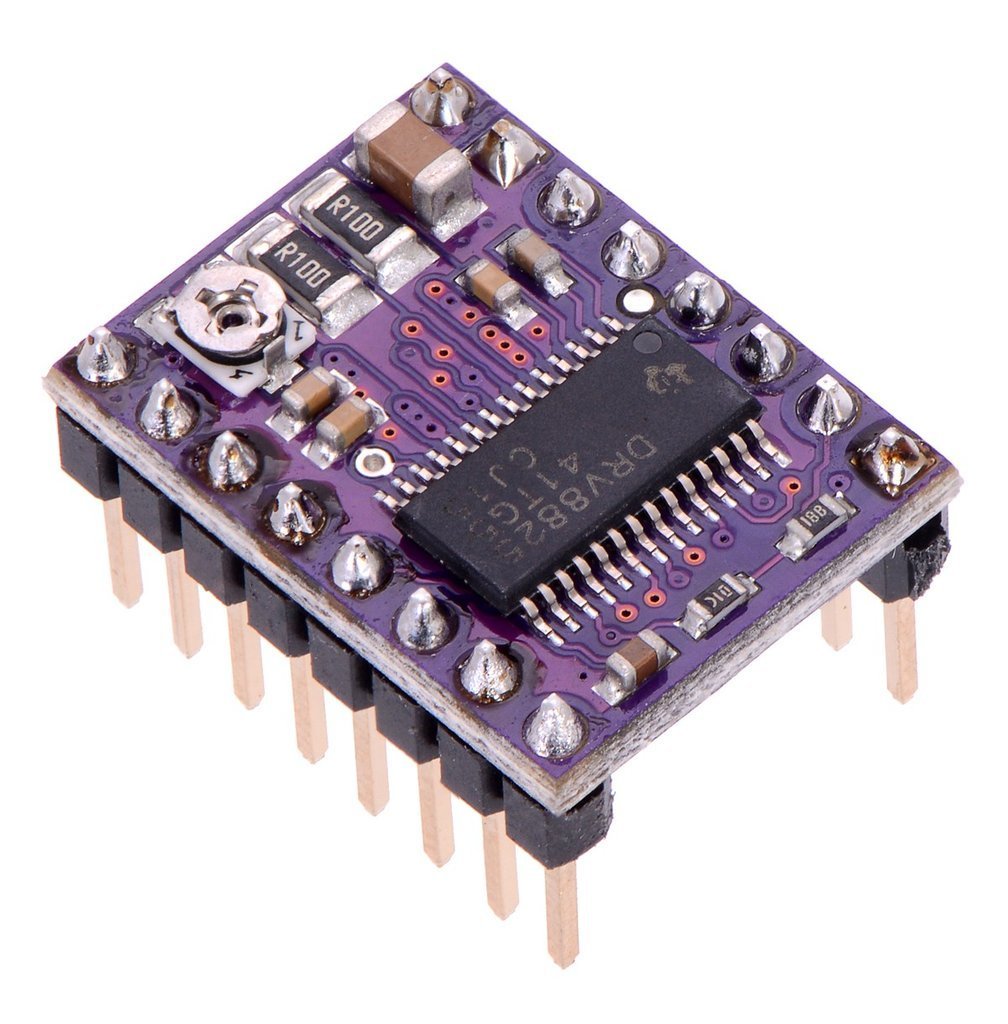

- DRV8825 Driver IC: Industry-standard driver offering smooth microstepping and reliable current control.

- Aluminum Heat Sink: Built-in heat sink improves thermal dissipation for stable operation under load.

- Microstepping: Configurable microstepping resolution up to 1/32 for finer positioning and reduced vibration.

- Adjustable Current Limit: Onboard potentiometer lets you dial in motor current to match your stepper and application.

- Protection Features: Includes thermal shutdown, overcurrent protection, and undervoltage lockout to protect the driver and motor.

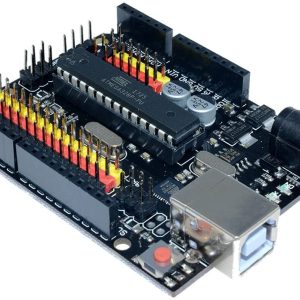

- Easy Integration: Standard pinout compatible with Arduino, Raspberry Pi, and most controller boards for quick setup.

Specifications

- Driver IC: TI DRV8825

- Microstepping Resolution: Up to 1/32 steps

- Operating Voltage: 8.2 V to 45 V

- Current Rating: Up to 2.5 A peak per coil (typical RMS current depends on cooling; recommended monitoring during setup)

- Heat Sink: Integrated aluminum heat sink included

- Interfaces: STEP, DIR, ENABLE, MS pins (for microstep selection), VMOT, GND

Compatibility and Applications

This DRV8825 module is suitable for a wide range of motion control projects:

- 3D printers and extruders

- CNC routers and milling machines

- Robotics and automated systems

- Camera sliders and pan/tilt rigs

- Precision positioning and laboratory equipment

Installation and Usage

Follow these guidelines to get reliable performance from your DRV8825 module.

Basic Wiring

- Supply VMOT and GND with a suitable motor power source within the recommended voltage range.

- Connect STEP and DIR pins to the pulse and direction outputs of your controller or microcontroller.

- Use ENABLE to enable or disable the driver as needed.

- Connect motor coils to the A+/A- and B+/B- outputs following your motor datasheet.

Microstepping Configuration

Microstepping is configured using the moduleâs microstep pins (MS/M0-M2). You can select full, half, quarter, eighth, sixteenth, and finer steps up to 1/32 for smoother motion and reduced resonance. Consult the module documentation for the exact pin combinations available on your board.

Current Adjustment and Tuning

- Adjust the motor current using the onboard potentiometer. Make adjustments gradually and monitor motor and driver temperature during setup.

- Always set the current limit according to your stepper motor rated current to avoid overheating or missed steps.

- Power off the board before making wiring or major adjustments.

Cooling and Mounting Tips

- Ensure adequate airflow around the aluminum heat sink for best thermal performance.

- For sustained high-current use, consider additional cooling such as a fan or larger heatsink.

- Mount the module on standoffs to improve airflow and prevent short circuits.

Protection and Reliability

The DRV8825 module includes built-in protection mechanisms to enhance durability and safety:

- Thermal shutdown to prevent damage from excessive temperature

- Overcurrent protection to guard against short circuits or stalled motors

- Undervoltage lockout to ensure stable operation when supply voltage falls below safe levels

Why Choose This Module

This DRV8825 Stepper Motor Driver Module with Aluminum Heat Sink combines precise microstepping, adjustable current control, and enhanced thermal performance in a compact, easy-to-integrate package. It is a reliable choice for hobbyists and professionals looking to upgrade motion control on 3D printers, CNC machines, robotics projects, and automated equipment.

Note: Images are for illustration purposes only. The actual product may vary slightly in appearance.

Reviews

There are no reviews yet