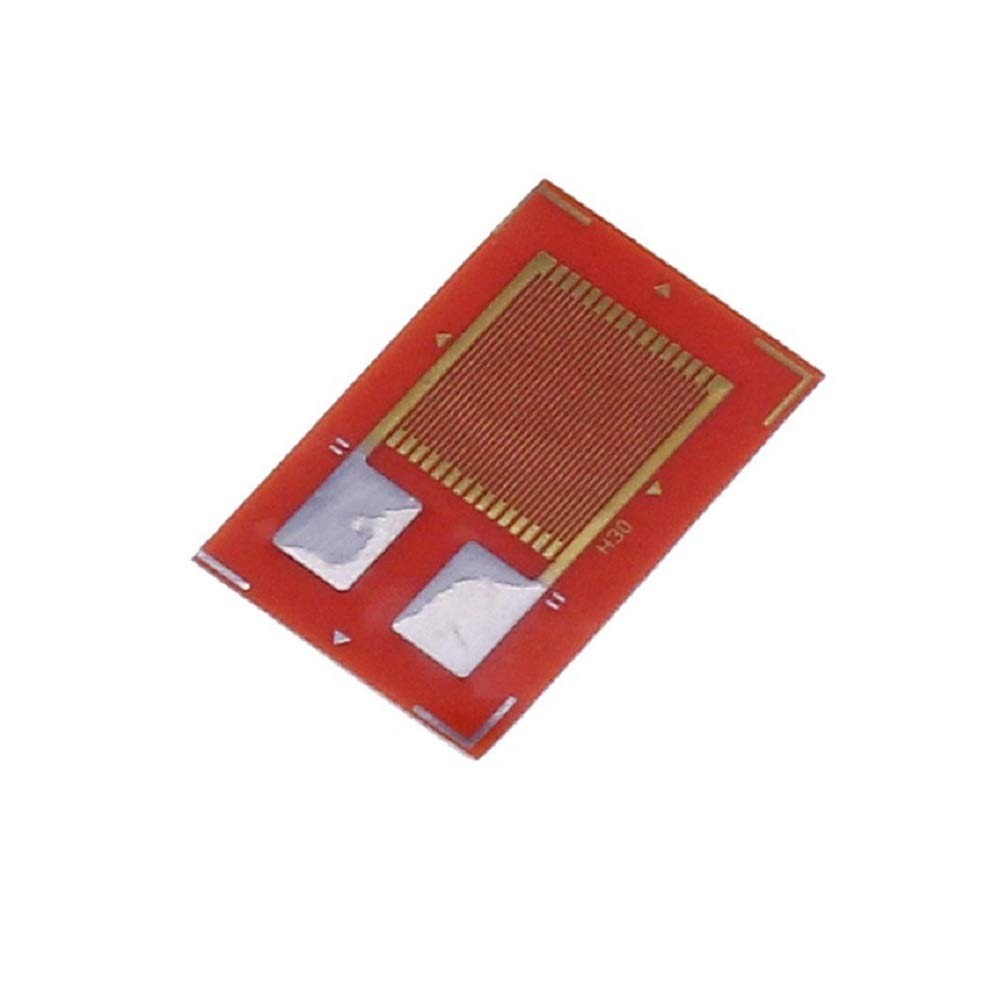

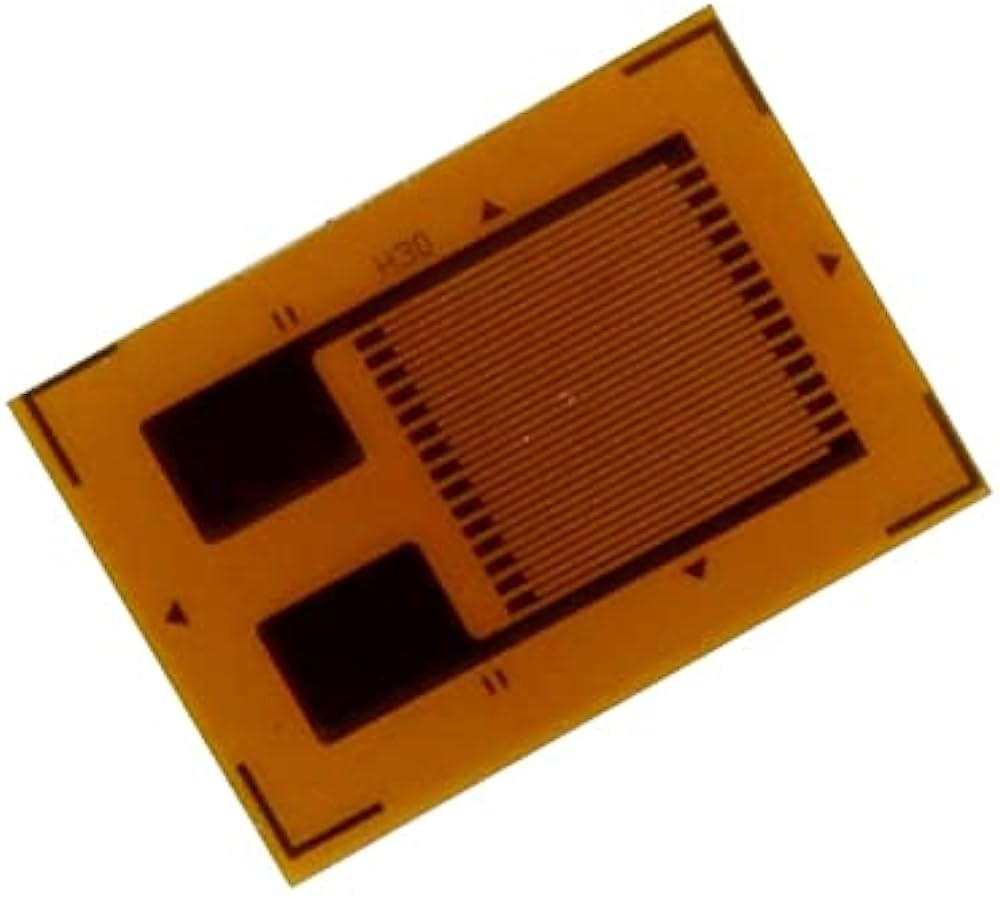

Overview: BF350-3AA Pressure Resistance Strain Gauge Sensor

The BF350-3AA Pressure Resistance Strain Gauge Sensor is a high-precision pressure sensor built on proven strain gauge technology. It converts mechanical strain caused by pressure into a stable electrical signal, delivering reliable real-time pressure data for industrial monitoring, testing and control systems.

Key Features

- High precision and stability — delivers consistent pressure readings with minimal error and low drift over time.

- Durable industrial design — engineered to withstand harsh operating environments and repeated mechanical stress.

- Compact and lightweight — easy to mount in tight spaces and integrate into existing systems.

- Wide application compatibility — suitable for hydraulic systems, automotive and aerospace components, HVAC systems, manufacturing equipment and R&D test rigs.

- Easy integration — designed for straightforward installation and compatibility with most pressure monitoring setups.

- Strain measurement technology — uses strain gauge principles to convert pressure-induced deformation into precise electrical outputs.

Applications

- Industrial equipment monitoring — manufacturing lines, presses and process control systems.

- Automotive — hydraulic systems, brake lines and fuel-system testing.

- Aerospace — pressure monitoring in critical aircraft systems and components.

- HVAC and refrigeration — ensuring safe, efficient operation of heating and cooling systems.

- Research and development — lab testing, material trials and precision experiments that require accurate pressure data.

Benefits for Your Projects

- Improved safety and reliability — accurate pressure feedback helps prevent overpressure conditions and equipment failures.

- Better process control — high-resolution measurements enable finer control of hydraulic and pneumatic operations.

- Reduced downtime — robust construction and stable readings minimize maintenance interventions.

- Flexible integration — compact form factor and industry-compatible outputs simplify retrofits and new designs.

Integration and Installation Tips

- Verify mechanical mounting points and ensure secure, vibration-resistant fixation.

- Match the sensor output and wiring to your data acquisition system or controller per your system’s input specifications.

- Perform an initial zero and span calibration after installation to confirm accuracy.

- Use appropriate protective fittings and seals if installing in corrosive or wet environments.

Maintenance and Calibration

- Regularly inspect wiring and mounting hardware for signs of wear or looseness.

- Schedule periodic recalibration to maintain measurement accuracy, especially after mechanical shocks or thermal cycling.

- Keep the sensing area free of debris and excessive contamination to ensure reliable readings.

Technical Considerations

- Signal conditioning — integrate with appropriate amplifiers or conditioners if your system requires specific voltage or current ranges.

- Environmental limits — select protective enclosures or coatings if operating outside typical industrial temperature and humidity ranges.

- Compatibility — confirm mechanical and electrical compatibility with existing gauges, manifolds and data acquisition hardware.

Ordering and Support

Contact your supplier or our sales team for lead times, custom options, and bulk pricing. Technical support is available to assist with integration, calibration and troubleshooting to ensure the BF350-3AA sensor meets your application needs.

Note: Images are for Illustration Purposes Only

Reviews

There are no reviews yet