Why the chassis matters for smart robotic cars

The chassis is the foundation of any smart robotic car. It affects weight, durability, sensor placement, thermal management, and even the vehicle’s behavior during maneuvers. Choosing the right material and design can make the difference between a prototype that fails in testing and a platform that scales into a reliable product. In this article we’ll dive into why an aluminium chassis for robotic cars is often the best choice for hobbyists, educators, and product teams building small autonomous vehicles.

Top benefits of aluminium for robotic car chassis

- Lightweight strength: Aluminium alloys, particularly 6061-T6 and 7075-T6, offer excellent strength-to-weight ratios. That means you get a rigid base without adding unnecessary mass, improving battery life and agility.

- Corrosion resistance: Aluminium naturally forms an oxide layer that resists corrosion. Anodizing further improves wear resistance and aesthetics.

- Thermal properties: Aluminium dissipates heat well, which helps when mounting motor drivers or SBCs (single-board computers) that generate heat.

- Machinability and fabrication: Aluminium is easy to CNC mill, laser cut, bend, or form—making rapid iteration and custom brackets straightforward.

- Recyclability and sustainability: Aluminium is highly recyclable, which matters for long-term product planning and environmental impact.

6061 vs 7075: Which alloy should you pick?

Two alloys appear frequently in chassis builds: 6061 and 7075. Here’s a practical breakdown:

- 6061-T6 — good corrosion resistance, excellent weldability and machinability, lower cost. Ideal for most educational and consumer robotic car projects.

- 7075-T6 — higher tensile strength and fatigue resistance, used where extreme stiffness and weight reduction are critical. More expensive and slightly harder to machine.

For most smart robotic cars, 6061 hits the sweet spot between performance, cost, and ease of fabrication. Use 7075 only when the chassis must be ultra-light and can justify the added expense and manufacturing complexity.

Fabrication techniques and finishing options

How you fabricate the chassis affects cost, lead time, and final quality. Common methods include:

- Laser cutting: Fast for flat plate designs with precise cutouts; ideal for 1-6 mm sheet aluminium. Good for rapid prototyping.

- CNC milling: Best for complex geometries, channels, countersinks, and integrated mounting features. Slower and pricier but delivers high precision.

- Bending/forming: Useful for adding rigidity with folded flanges and flange-mounted brackets.

- Anodizing: Surface anodization boosts corrosion and wear resistance and provides color options for branding or classroom kits.

For many teams, a hybrid approach works best: laser-cut the baseplates and CNC mill high-precision mounting bosses or sensor pods.

Design considerations specific to smart robotic cars

When designing or choosing an aluminium chassis, focus on mechanical and system-integration details:

- Thickness: Small hobby cars often use 1.5-3 mm sheets; larger or load-bearing platforms may use 4-6 mm or add internal ribs for stiffness.

- Mounting versatility: Include multiple M3/M4 mounting patterns and slots for adjustable motor, battery, and sensor placement.

- Center of gravity: Keep heavy components (batteries, motors) low and centered to improve handling. Design battery trays and motor mounts accordingly.

- Modularity: Use removable plates or stackable layers to separate power, compute, and sensors. This speeds debugging and upgrades.

- Sensor integration: Design dedicated mounts for LiDAR, stereo cameras, ultrasonic sensors, IMUs, and antennae with clear fields of view and cable routing.

- EMI grounding and shielding: Aluminium can act as a grounded conductive plane—use it strategically to reduce EMI for radios and GPS modules.

Real-world examples and use cases

Aluminium chassis are widely used across applications:

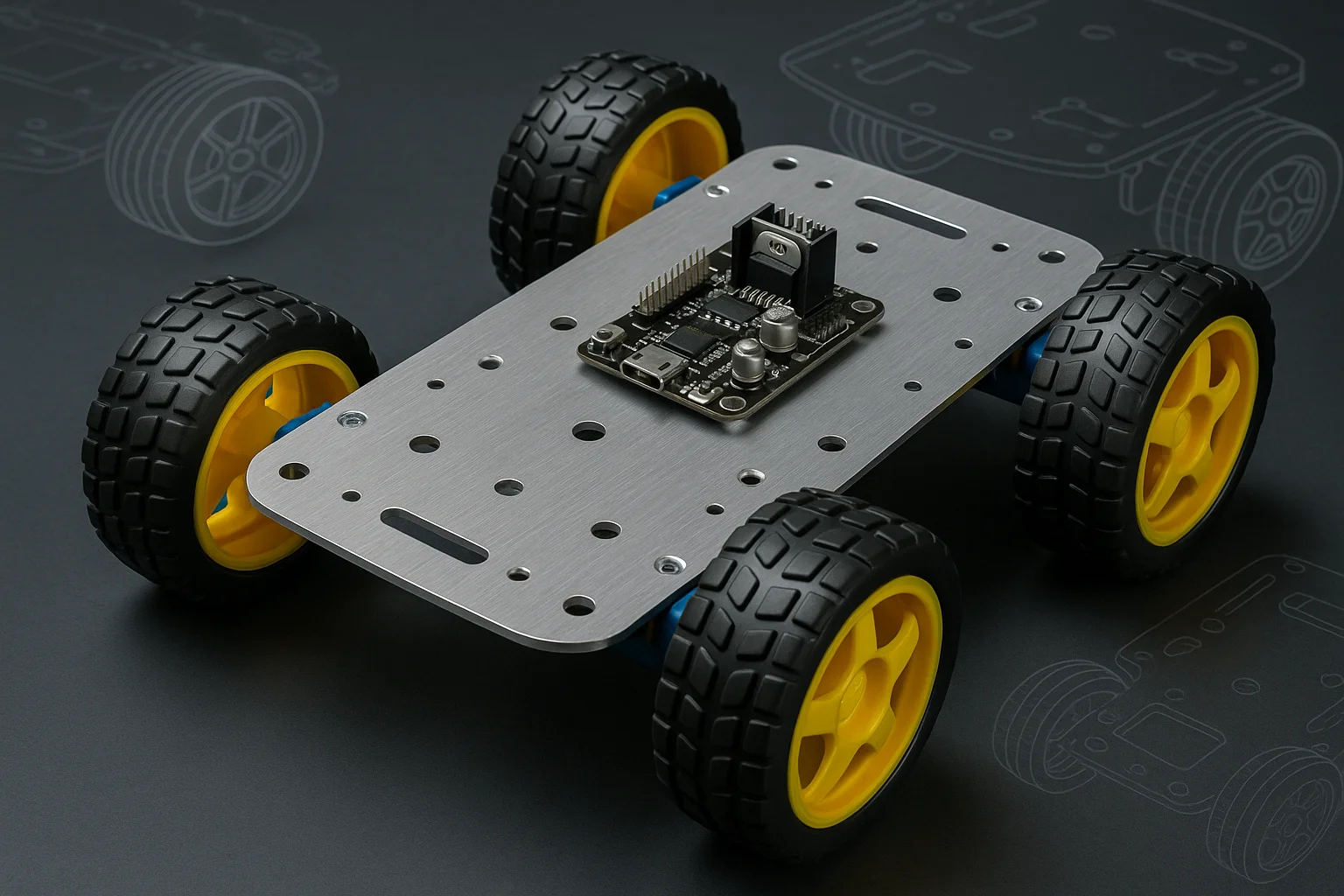

- Education and hobby: Affordable laser-cut aluminium kits provide durable platforms for Arduino, Raspberry Pi, and micro:bit-based robot cars.

- Research prototypes: University teams prefer aluminium for repeatable, modifiable platforms used in perception and autonomy experiments.

- Low-speed delivery robots / last-mile runners: Small commercial platforms benefit from aluminium’s balance of weight and durability.

- Competitions and demos: Anodized aluminium chassis offer the rigidity and finish expected in demonstrations and contests.

Many starter kits bundle anodized aluminium plates with motor/encoder mounts and wheels—an excellent way to get practical experience with mechanical integration.

Cost and manufacturing trade-offs

Budget impacts choice:

- Low-cost builds: Use 1.5-2 mm 6061 plates cut by laser and bent locally. Standard finish is bare or chemically treated to prevent staining.

- Mid-range: Add anodizing, integrated standoffs, and a few CNC-milled parts for precision sensor mounts.

- High-end: Choose 7075 where weight is critical, fully CNC parts, and custom anodized finishes. Expect higher per-unit costs but professional results.

Prototyping with laser-cut parts reduces upfront costs and shortens iteration cycles. CNC is best once your design stabilizes.

Maintenance and longevity

Aluminium chassis are low-maintenance but follow these tips to extend service life:

- Keep anodized surfaces clean; avoid aggressive solvents that strip anodic layers.

- Inspect threaded inserts and use helicoils or rivet nuts for repeated assembly cycles.

- Check mounting fasteners for loosening from vibration; use threadlocker on critical joints.

- Repair minor dents with gentle reshaping; replace heavily deformed panels to keep alignment for sensors and wheels.

Recommended specs and a simple parts checklist

For a versatile smart robotic car platform that supports SBCs (Raspberry Pi/Jetson), sensors, and two motors, consider this starting spec:

- Material: 6061-T6 aluminium plate

- Thickness: 2-3 mm base plate, 3-4 mm for motor mounts or load-bearing brackets

- Finish: Type II anodize (optional) for wear resistance

- Mounting: M3 and M4 standoffs and slots, captive rivet nuts for repeated assemblies

- Extras: integrated cable channels, rubber vibration mounts for sensors, dedicated GPS, and antenna mounts

Why choose an aluminium chassis for robotic cars today

An aluminium chassis for robotic cars blends practicality with performance. It’s lightweight enough for battery-powered autonomy, robust for repeated testing, and flexible enough for rapid iteration. Whether you’re building a classroom robot, a research testbed, or a prototype for a commercial small vehicle, aluminium gives you a practical path from idea to working system.

Key takeaways and next steps

To summarize:

- Aluminium delivers an excellent strength-to-weight ratio, corrosion resistance, and thermal advantages.

- Use 6061 for most applications; choose 7075 for top-end weight-critical designs.

- Mix laser cutting and CNC milling to balance cost and precision during development.

- Design for modularity, low center of gravity, and easy sensor integration.

If you’re building your first smart robotic car platform, start with a laser-cut 6061 chassis and a simple modular layout. Iterate to add CNC-milled features and anodizing once your design matures. For market context, smart vehicle and robotics investments have been growing — demand for reliable, modular platforms like aluminium chassis continues to rise (see industry reports) [source].

Next steps: sketch your layout, choose a plate thickness in the 2-3 mm range, and prototype with laser-cut parts. When your design stabilizes, lock in critical mounting features with CNC machining and consider anodizing for durability.

Further reading & resources: look up fabrication shops that offer combined laser-cut + CNC services, check anodizing options locally, and review community projects that publish CAD files to accelerate your build.

Good luck with your robotic car project — a well-designed aluminium chassis will make all the difference.