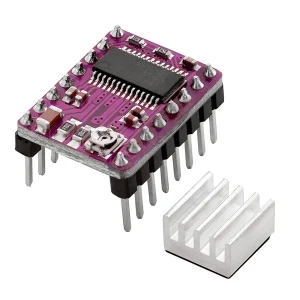

TB6600 Stepper Motor Driver Module Overview

The TB6600 Stepper Motor Driver Module is a rugged, high-performance driver based on Toshiba’s TB6600 IC. Engineered for reliable stepper motor control in CNC machines, 3D printers, robotics and industrial automation, this module delivers precise motion control with advanced protection and flexible configuration.

Key Features

- Wide voltage input: 9V to 40V DC supports a broad range of stepper motors and power supplies.

- High adjustable current: 0.5A to 4.5A (adjustable) to handle low- to high-torque motors.

- Microstepping: Selectable full, 1/2, 1/4, 1/8 and 1/16 microstepping for smoother, quieter operation.

- Protection: Integrated overcurrent, overvoltage and thermal protection to safeguard the driver and motor.

- Efficient cooling: Durable aluminum casing improves heat dissipation during continuous use.

- Flexible control: Standard DIR (direction), PUL (pulse) and EN (enable) interface; supports PWM control and direction signals.

Technical Specifications

- Driver IC: TB6600

- Input Voltage: 9V to 40V DC

- Current Output: 0.5A to 4.5A (adjustable)

- Microstepping: Full, 1/2, 1/4, 1/8, 1/16

- Control Interface: DIR (direction), PUL (pulse), EN (enable)

- Operating Temperature: -10°C to +45°C

- Dimensions: 96mm x 56mm x 32mm (approx.)

Pinout and Control Interface

- DIR: Direction input — set motor rotation direction.

- PUL: Pulse input — step pulses to advance motor steps.

- EN: Enable input — enable or disable driver output.

Installation and Wiring Tips

- Use a properly rated power supply within the 9V to 40V range. Avoid voltage spikes on startup.

- Set the current limit using the onboard potentiometer to match your stepper motor’s rated current (start lower and increase as needed).

- Wire motor coils correctly and keep motor and driver ground common with the controller (e.g., Arduino, GRBL controller).

- Route step and direction signal wires away from high-current motor wiring to reduce electrical noise.

- When using long cable runs, add shielding or use twisted pair wiring for pulse and direction lines.

Cooling, Protection and Reliability

- The aluminum casing provides passive heat dissipation; install in a ventilated enclosure for continuous high-current operation.

- Built-in thermal shutdown, overcurrent and overvoltage protection help prevent damage from misuse or short circuits.

- For prolonged high-load use, consider adding a small fan or heatsink-mounted airflow to maintain optimal operating temperature.

Compatible Applications

The TB6600 Stepper Motor Driver Module is ideal for:

- NEMA stepper motors in CNC routers, mills and laser cutters.

- 3D printer motion control and axis drivers.

- Robotics projects requiring precise position control and torque.

- Engraving, plotting and pick-and-place machines.

- Industrial automation prototypes and research projects.

Why Choose the TB6600 Stepper Motor Driver Module

Combining a wide voltage window, adjustable high-current output up to 4.5A, microstepping to 1/16 and robust protection features, the TB6600 Stepper Motor Driver is a versatile, dependable choice for both hobbyists and professionals. Its durable aluminum housing and flexible control interface make it simple to integrate into CNC, 3D printing and robotic systems that demand consistent, accurate motion control.

Note: Images are for illustration purposes only. Actual product design and appearance may vary.

Reviews

There are no reviews yet