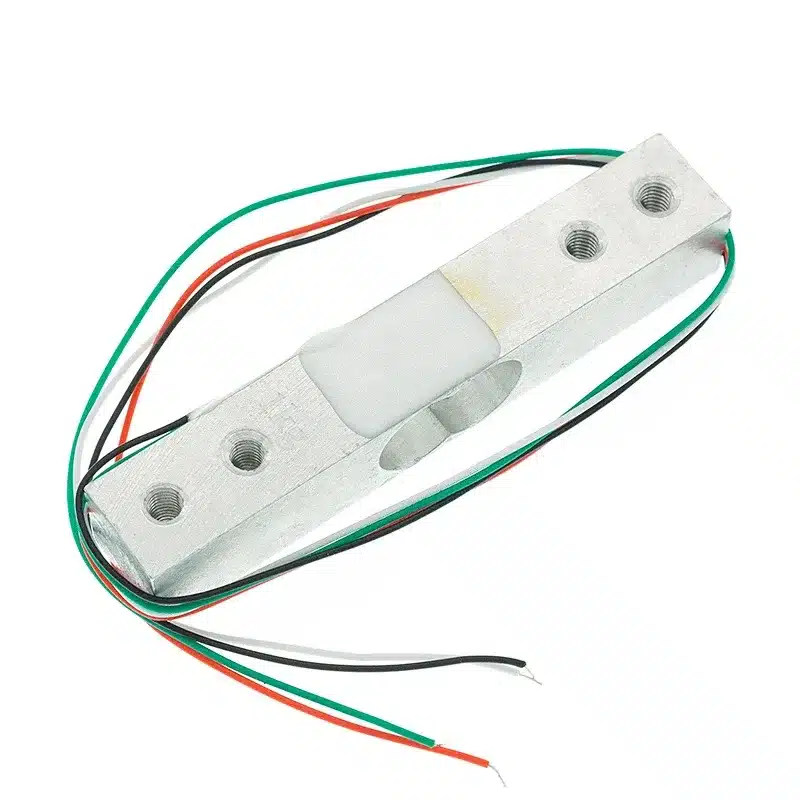

Product Overview: 10kg Aluminum Weighing Load Cell Sensor

The 10kg Aluminum Weighing Load Cell Sensor is a compact, high-precision sensor designed to measure loads up to 10 kilograms. Manufactured from high-quality aluminum alloy, this load cell delivers reliable weight sensing with low weight and easy integration for hobbyist and industrial projects alike.

How it Works

This load cell uses strain gauge technology arranged in a Wheatstone bridge configuration. When a load is applied, the strain gauges change resistance, producing a small differential voltage proportional to the applied force. For stable digital readings, pair this sensor with an HX711 amplifier module or a compatible ADC designed for load cells.

Key Features

- Load capacity: 10kg

- Material: Aluminum alloy (lightweight and durable)

- Four strain gauges in a Wheatstone bridge for improved accuracy and temperature compensation

- Compact footprint with mounting holes for straightforward installation

- Simple 4-wire connection: E+ (excitation+), E- (excitation-), A+ (signal+), A- (signal-)

- Designed for use with HX711 amplifier module for digital output

- Suitable for both DIY and industrial applications

Specifications

- Maximum capacity: 10 kilograms

- Construction: Aluminum alloy

- Output type: Strain gauge (Wheatstone bridge)

- Connection: 4-wire (E+, E-, A+, A-)

- Typical applications: Digital scales, kitchen scales, postal/package weighing, robotics, automation, laboratory weighing

Wiring and Integration

For reliable digital readings, connect the load cell to an HX711 amplifier module or equivalent ADC. Typical wiring:

- E+ (Excitation +) -> HX711 E+ / VCC reference

- E- (Excitation -) -> HX711 E- / GND reference

- A+ (Signal +) -> HX711 A+ / Input+

- A- (Signal -) -> HX711 A- / Input-

After wiring, calibrate your system in software to convert ADC counts to kilograms. Use stable mounting and a reference weight for accurate calibration.

Mounting and Installation Tips

- Install the load cell on a flat, rigid surface to avoid torsion or uneven loading.

- Use the provided mounting holes and tighten bolts evenly to prevent bending stress.

- Keep wiring away from high-current traces and motors to reduce electrical noise.

- Perform calibration after final mechanical assembly for best accuracy.

Common Applications

- Digital weighing scales and kitchen scales

- Postal and package weighing stations

- Robotics for force and payload measurement

- Automation systems requiring weight feedback

- Laboratory and light industrial weighing setups

Note: Images are for Illustration Purposes Only.

Anonymous (verified owner) –

It was very good experience

Anonymous –